2020-10-19

With the rapid development of the plastics industry today, injection molding machines occupy an important position in terms of quantity and variety. The injection molding machine has the function of being able to mold plastic products with complex appearance, precise size or dense texture with metal inserts at one time. It is widely used in national defense, electromechanical, automobile, transportation, building materials, packaging, agriculture, culture, education and health. All areas of people’s daily lives. The market is full of injection molding machines of various models and different purposes. How to buy a satisfactory injection molding machine and what to pay attention to when purchasing an injection molding machine has always been a difficult problem for users. Let's take a look at what you need to pay attention to when purchasing an injection molding machine.

Purchasing point 1: Technical parameters of the injection molding machine. When users choose injection molding machines, they can be judged by vertical or horizontal comparison. The so-called "longitudinal" means that the main technical parameters of the injection molding machine should meet industry standards and be reviewed according to industry standards. The so-called "horizontal" is to compare the technical parameters of similar injection molding machines at home and abroad. Therefore, this is a very careful scientific work. According to the material, shape, structure, and application fields and specific occasions of injection molded products, according to the structure, quality, precision, number of cavities, type of runners, and structure, shape and size of the mold, according to the day, month, and size of the product The annual production capacity and the degree of automation are used to select the parameters of the injection molding machine at all levels.

Purchase key two: the stability, reliability, safety and service life of the machine. The stability of the machine is mostly manifested in whether the clamping mechanism and the injection molding system are running smoothly in each cycle, working under noise-free and silent, and the noise must not exceed the industry standard. These conditions are related to the mechanical manufacturing and assembly accuracy, as well as the reasonable design and structure of the toggle link. Reliability and service life are mainly reflected in the system rigidity of the clamping mechanism, which is related to the structure, size, material and heat treatment process of the template, tie rod, connecting rod and pin shaft; the plastic warping system of the injection molding machine such as the barrel The structure and manufacturing process of the screw, screw, screw head, non-return ring, and screw drive spindle are the main stress and wear parts of the injection molding machine, which directly affect the service life.

Purchase key three: the safety of the injection molding machine. When the mold clamping mechanism opens and closes the mold, the reliability of the low-voltage protection system involves human-machine safety. Injection molding machines must implement a combined electrical, mechanical, and hydraulic safety protection system. This protection mainly reflects two aspects: one is the safety protection of the mold, and the other is the safety protection of the person. Before closing the mold, when the safety door is not closed, the mold closing should not be able to move; during the closing process, if the safety door is not closed to the correct position, the template action stops or the mold opens automatically. If, during mold closing, foreign objects such as inserts fall into the cavity due to vibration, or other foreign objects are mistakenly inserted into the mold, the mold should stop the mold closing action, or automatically open the mold and give an alarm .

Another safety aspect of the injection molding machine is to prevent cold start of the pre-plastic screw. When the material of the screw does not reach the specified temperature and holding time, it is forbidden to start, otherwise an alarm will occur. The protective device of the injection molding machine nozzle splash is necessary to prevent burns.

Purchase points four: high degree of automation, complete functions and high production efficiency. Modern injection molding machines can be operated manually, semi-automatically, and fully automatically. As long as the mold design is reasonable, the fully automatic operation from injection molding to ejection and dropping of the product can be realized, and it can also be equipped with a robot to realize unmanned operation. The insert core function, hydraulic nozzle control function and fast heating runner probe function can all be programmed into the automatic program in the injection molding cycle for automatic circulation. The high production efficiency is mainly reflected in the short molding cycle of each molded product under normal injection molding process conditions. This reflects the comprehensive performance indicators of the mechanical, electrical, and hydraulic systems of an injection molding machine. Therefore, it is necessary to use high-quality hydraulic and electronic components and sophisticated manufacturing techniques to improve the sensitivity and repeatability of the injection molding machine system. The efficient operation of the injection molding system is a reliable guarantee.

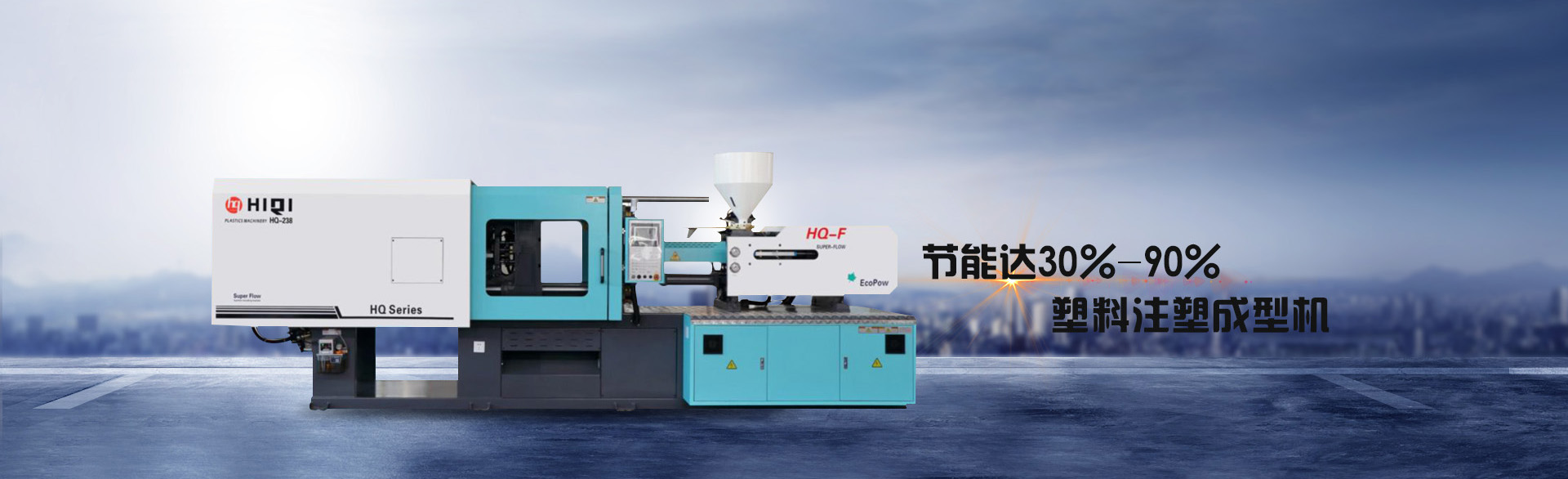

Purchase key five: Energy saving and environmental protection is an important indicator for judging the pros and cons of injection molding machines. Energy saving mainly reflects the water-saving and power-saving capabilities of the injection molding machine when the heating system (electromagnetic heating), power drive system (frequency converter, server, etc.), and cooling system meet the normal process conditions compared with similar machines. Injection molding machine design should fully consider the theme of "environmental protection". The injection molding machine should prevent hydraulic oil leakage or excessive noise in order to create a quiet, noise-free working environment. In addition, the injection molding machine itself should also use more environmentally friendly materials.

Purchase points six: machine maintenance and overhaul should be convenient. The installation position of various machines such as mechanical, hydraulic, electronic, and electrical components should be conducive to the maintenance and repair of the machine. At the same time, the generalization and standardization of injection molding machines are also very important to users.

In addition, the production cost, production efficiency, suppliers and operability of the injection molding machine are all things that should be considered when purchasing an injection molding machine.

|

Mobile version

Mobile version WeChat public account

WeChat public account